Chapter 7. Pro Tips and The Nitty Gritty of the Packaging Process

Now, you have an overview of what the process looks like. So, here we have the nitty gritty that applies to the top printing and packaging processes you need to know for custom packaging.

We will start with the software commonly used for this process.

Top Software to Try

Some top software work for the artwork or the first step for printing, like:

Adobe Photoshop is among the top software you can use to design your digital file. These files are directly used in printing by feeding this digital information into the printing machine.

PSD is one of the common files you can use for this design process. Other files in AI files that you can create in Adobe Illustrator. CDR or Correll Draw files are another type you can try if you are a limited-budget company.

What Files to Send To Your Printing Company

If you are a printing company, you can use several methods to send them your design file. It will vary according to your expertise and your provider’s expertise. You can also impact the fee you offer them if you do some part or most of this designing process.

There are some common ways you can send your design:

- If you are a design expert, you can offer your provider a complete design they may use for your job.

- You can also ask for a template from your provider.

- Also, you may get a template and make changes to let your provider have a file for the printing processes.

Keep this information in mind even if you are creating custom clothes packaging. These work for custom-made stickers as well.

What Should a Softcopy Design Have?

Well, this question must be in your mind as a client or manufacturer. You need to make sure that you include all the most essential information in your softcopy design, like:

- Your typography and fonts are an integral part of your design.

- The patterns you want to have in your print products should also be there.

- It should have specific dimensions that you want to use for your custom boxes.

One thing is for sure you can play with different design features that you need to have in your end product. For instance, you can change your custom box sizes, designs, colors, and other features that a softcopy design should carry. Your printing machines get their input from the files you need to provide before the printing process starts.

So, prepare one as a client or ask your provider to offer you one. On the other hand, as a provider, you should have a department to make these designs. Your designs may also carry a press line and registration marks, and you should check your colors separately in CMYK color tone.

Check these designs separately; they should be clean and should not overlap with others. Try following this method even if you are creating custom clothes packaging.

Perfect your Softcopy With……..?

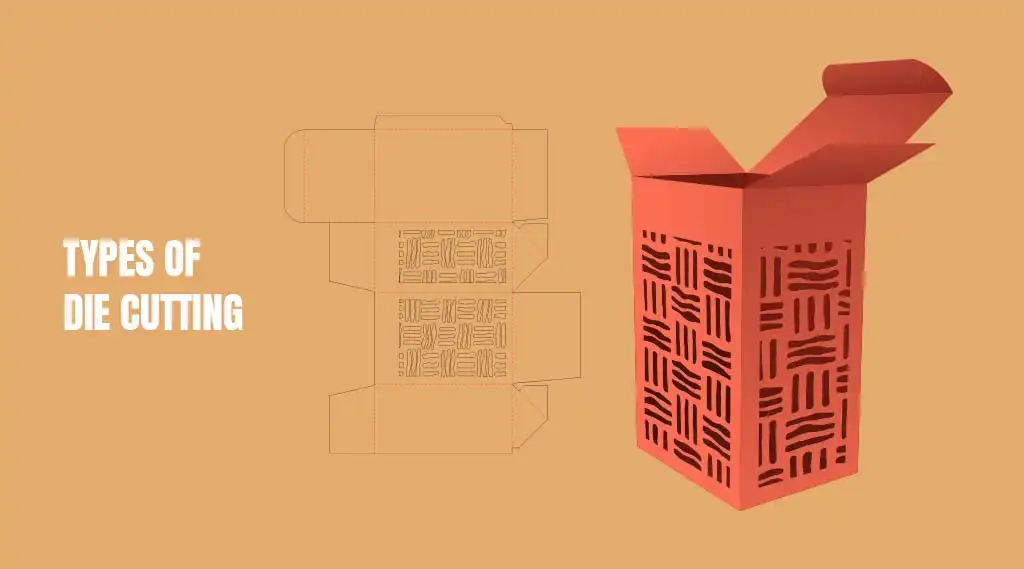

When cutting designs, you need to have logos and taglines in the softcopy you create for the design. Make sure you have all the dimensions you need to create your boxes. There are several types of die cutting that you can try out.

Types of Die Cutting

For instance, some companies use laser cutting for making stickers and other products. Also, you can create inserts and foams for your custom boxes with this technology.

Then there are ways like manual die cutting that is a process. So, you use dies and blades for its cutting and then set it to the machine. Next, you should heat it and cut it with that.

Rotary cutting is one of the most common die-cutting types that you can try out. Then there are several effects and designs you can try for your printing processes. For instance:

- You can try using case-making for your custom box.

- Also, you can get a multiple-point glow on your box.

- Then there are special effects for your boxes.

When it comes to custom boxes, you can have sizes as you like, with a difference in inches or even lower than that.

Types of Mock-ups

Mock-ups can help your clients determine if they need a certain type of print. So, some top mock-up types for this purpose are:

- You can send them a flat design

- Sending a 3D mock-up is also a norm

- Try using a hand-made dummy of the box as a sample as well.

When you think you have your client, using physical samples is a great idea. For this purpose, you can get some of the payment from them and send them a sample.

Then you can cut your boxes according to your design needs and turn them into what you need. So, you can need to cut your boxes according to your needs. So, you can use this custom packaging for product tips to get better results for your branding and promotion.

New Technologies

As far as new technologies are concerned, you can use things that work well for the purpose. For instance, you can try using technologies that complete all the processes inside your machine.

You can try out other technologies for better results for printing and packaging jobs. Then there are cutting sheets manually, and older technologies were utterly different. For instance, you would have to print every color separately in some older technologies.

At the same time, you might have to add special effects separately to make your content special. You can try creating custom boxes for businesses with these new technologies. So, these technologies offer custom packaging for business needs.

Quality Assurance

The quality assurance process is another one that every print job needs. So, you need a system that works perfectly to get you more sales and better results. One of the methods for any quality assurance will be to check manually to make your printing flawless.

On the other hand, some companies have separate departments for quality assurance. While others do not have any departments, the production head would also keep an eye on print quality. So, you can ensure better quality with manual checking.

In some companies, the quality assurance manager also does the assembling job. This way, you can get custom packaging for products for any needs.

So, if you are creating custom boxes for the business, you need to follow the process that works for it. Like custom boxes, you can use custom-made stickers to perfect your results. Different box design ideas would work for different needs you should keep in mind.

Final Thoughts

So, this guide must have been a lot of help as this information can transform your promotion efforts. You need to make it an easy job, from designing your box graphics, logo, design, and typography to the end. Knowing your design elements ensures better performance for your products for any platform.

Still, you need to work super hard to learn everything about your customers and brand. Try to find what your brand should look like and what colors suit it most. Ensure you understand where the product will display, an online platform or a local store.

Also, perfect your material decisions and use the pro tips for a perfect quality assurance process. Ensure you know different custom box types, the materials you can use, and how to send a mock-up.

Try different methods to send mock-ups according to what suits you best and works in your industry.

Plus, carefully choose between different materials and box types till you find the best one. Moreover, you can learn about different paper grades and top eco-friendly materials for your custom box production.