Chapter 6. Printing Types For Custom Boxes?

Printing is an essential part of making custom boxes and their design. So, you can read about the top offset printing types you need to know.

Top Printing Types For Custom Box

| Web fed printing | Web-fed printing offers more processing speed and is still a cost-effective method. |

| Sheet-fed printing | Sheet-fed printing allows you fast processing when you use UV effects. Also, it offers quality with the best fiber direction and a wide range of formats. |

| Flexographic Printing | Flexographic printing offers a speedy process with good image quality on your custom boxes. |

| Digital Printing | Digital printing works for full-color jobs has quick delivery, does not cost you as much, and is environmentally friendly. |

| Silkscreen Printing Benefits | This printing method offers durability with high-quality images. |

Offset Printing

Offset printing can be super effective for several benefits from printing processes. This technology works for several packaging and printing jobs. So, you can try it as a custom packaging printer for results.

Web fed printing

Web-fed printing is a top offset printing type that works incredibly well. So, you can choose between web-fed and sheet-fed methods according to your needs.

Some Top Benefits of Web Fed Printing

Web-fed printing allows you more speed as it offers hundreds of thousands of feet of paper printing every hour. Moreover, there is no need to reload sheets in these machines. At the same time, you can change its plates quickly.

It allows cost-effective solutions, making it a preferred method for your processes. In addition, this method will enable you to work on multiple types of projects efficiently. Another benefit you can reap is getting quality products from this machine, which is perfect for bigger orders.

It is a perfect method to get custom packaging printer outcomes.

Sheet-fed printing

Sheet-fed printing may not offer quick processing when you use UV. However, this method also offers great quality, and you can select the best fiber direction. At the same time, it can print from various formats. Using this method also gives you a wide range of colors to choose from.

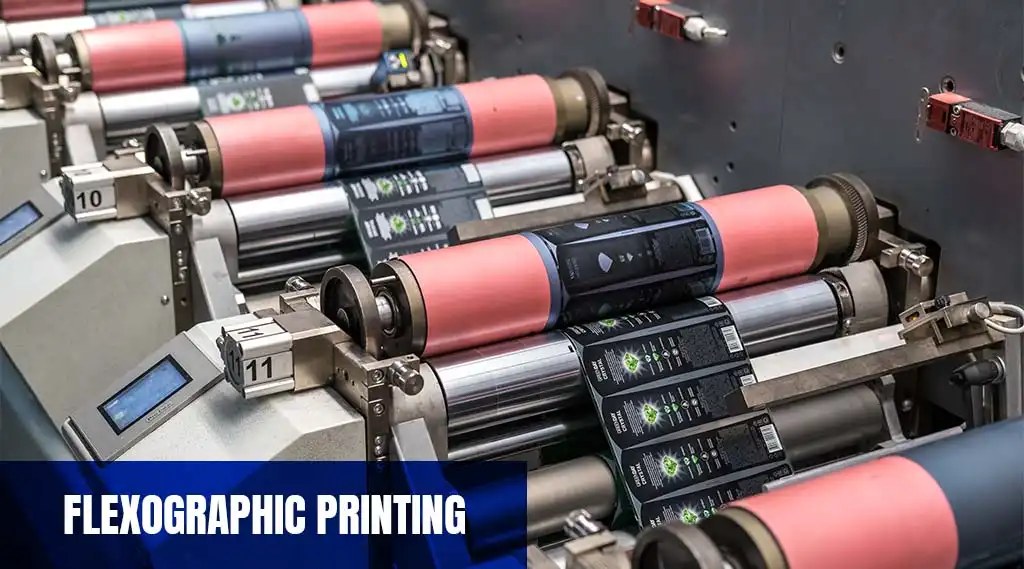

Flexographic Printing

So, using this method for custom packaging can bring you multiple benefits. For instance, you can have a broader range of patterns and solid colors on substrates. Moreover, it offers you extensible substrates. At the same time, this method provides you with multiple ink types.

One thing is for sure: you need a speedy process with a good image quality that you produce. For instance, you can try water-based, UV-curable, and solvent-based inks. Another essential benefit of this method is saving a good amount of ink during the process.

Getting this process reduces your overall cost, making it a preferred method you can try. Also, if you want your process to be sustainable, you can rely on the flexography printing method.

Digital Printing

Digital printing is a perfect method that offers you the benefits of printing custom boxes. For instance, you can use it for full-color jobs with quick delivery, which does not cost as much as other methods. One thing is for sure: it is one of the most straightforward methods in the printing world.

It even works for environmentally friendly jobs, making them custom boxes. But, on the other hand, it has the drawback of not being efficient for bigger production jobs.

Silkscreen Printing Benefits

Silkscreen printing has its benefits, like durability and high-quality results. Moreover, it allows you distinctive branding and a wide print area.

Custom Boxes Offset Printing Process

It all starts with making artwork for your printing job. Make sure that you take a professional’s help to design well. Use the CMYK color code from RGB.

- Make sure you layer your graphics on a plate that can be a metal sheet.

- Then, you can transfer your plate to a rubber roller or cylinder mold.

- You can use this one to make the printing process.

- Also, you can use two plates for the prints you need for both sides of the process.

- Next, the roller will start feeding the paper into the press, and then you can get artwork stamps on the paper.

Custom Boxes With Flexographic Printing

This process also starts with the artwork process. So, here we go:

- You can have a rolling design for a flexographic printing press, which you can use for continuous substrate feeding.

- Then your substrate goes into the printing press, and you can enclose the chamber with ink.

- Then, the press transfers the ink, removing excess ink.

- Following microscopic cells carry the ink to the image carrier.

- In the following process, your printing press pulls the substrate between the image carrier and the impression cylinder.

- After this process, the drying of the ink starts, and you can have different section types to dry it.

- The last step is cutting the die, separating individual prints in the outfeed, and rewriting the part.

Choosing the right Printing Method for Your Custom Boxes

When choosing different custom box printing methods, you must be vigilant. Make sure you use digital or flexographic printing when you want complex patterns. You can try using a flexo box if you want a cost-effective choice of the same design for bulk orders.

It also provides you with multiple unique service materials, which can improve your printing results. At the same time, you should consider your deadline before choosing any printing type. A project will choose Flexo box printing for quick turnaround.

Next, you can read pro tips about creating fantastic packaging results with technical details you should know.